Feintool Bags Major Contract For Electric drives With Innovative Bonding Technology

CIOTechOutlook Team | Friday, 14 July 2023, 11:41 IST

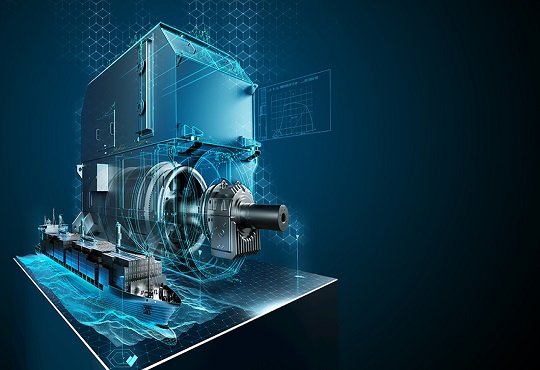

American original equipment manufacturer (OEM) has given Feintool a multi-year contract. The six-year deal is for the supply of stators and rotors for e-cars' primary drives, with a lifetime volume estimated to be in the three-digit million euro range.These components will be produced using the ground-breaking and patented Glulock MD bonding technique for the first time in a high volume setting. The achievement of this important contract highlights the exceptional performance of Feintool's distinctive Glulock MD technology.

American original equipment manufacturer (OEM) has given Feintool a multi-year contract. The six-year deal is for the supply of stators and rotors for e-cars' primary drives, with a lifetime volume estimated to be in the three-digit million euro range.These components will be produced using the ground-breaking and patented Glulock MD bonding technique for the first time in a high volume setting. The achievement of this important contract highlights the exceptional performance of Feintool's distinctive Glulock MD technology.

The next generation of electric car drives will rely heavily on this customer-specific bonding procedure with enhanced mechanical and electromagnetic qualities. Nearly full-surface bonding is accomplished by using many carefully positioned adhesive dots on the sheet metal, effectively satisfying the necessary tightness requirements. Direct motor cooling improves the e-machine's efficiency as a result. Additionally, the yoke and tooth components' bonding ensures maximum stability.

Starting in the second semester of 2026, one of the facilities in the Stamping business unit will create the drive components. The motors inside the more than 800,000 rotor-stator sets used to make electric vehicles in Europe.

Torsten Greiner, CEO Feintool, is delighted: "This contract with a renowned OEM strengthens our company as a leading manufacturer of rotors and stators for electrically powered passenger cars. The fact that our patented Glulock MD adhesive bonding technology is being used shows that our technologies are mature and are gaining traction in the electric mobility market."

CIO Viewpoint

AI Appreciation Day: Powering Smart Factories,...

By Janifha Evangeline, Editor, CIOTechOutlook

Why Foolproof Facial Recognition Is Key Against...

By Joseph Sudheer Thumma, Global CEO & MD, Magellanic Cloud

National Technology Day 2025: Powering Progress...

By CIOTech Outlook Team

CXO Insights

5G Will Bring A Data Tsunami: Can Your Data...

By Nikhil Korgaonkar, Regional Director, Arcserve India & SAARC

Machine Learning Trends In 2021

By Kavitha Siddada, Head - Design Engineering, Shell

The Rise Of Developer Led Innovation &...

.jpg)