How Businesses Use Metaverse and Digital Twins to Innovate Product Design

Grena, Correspondent, CIOTechOutlook | Sunday, 22 June 2025, 07:59 IST

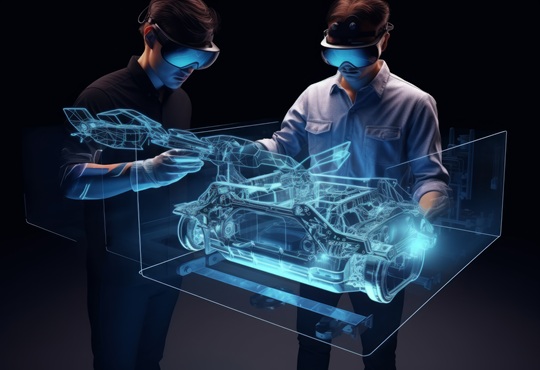

Product design is changing rapidly with the advent of technologies such as the Metaverse and Digital Twins. These technologies allow businesses to move away from outdated product design processes by offering immersive 3D collaborative spaces and fast-paced virtual simulations of products being tested in real-time. While the Metaverse allows for the exploration and iteration of various product ideas in an engaging interactive environment, Digital Twins provide insights into real-world data by recreating real-world behaviors.

Product design is changing rapidly with the advent of technologies such as the Metaverse and Digital Twins. These technologies allow businesses to move away from outdated product design processes by offering immersive 3D collaborative spaces and fast-paced virtual simulations of products being tested in real-time. While the Metaverse allows for the exploration and iteration of various product ideas in an engaging interactive environment, Digital Twins provide insights into real-world data by recreating real-world behaviors.

"It's not just a gimmick - it's actually a very powerful tool for engineers and designers to make decisions," Mike Rockwell, vice president of Apple's vision products group, told Reuters. "You're able to make these decisions earlier in the process, and that can save you huge amounts of money and time and rework."

The synergy between the Metaverse and Digital Twin technologies enhances the product design processes and development, reduces timeframes, reduces costs, and enhances quality of product innovation.

Revolutionizing Product Design through the Metaverse

The Metaverse is changing the future of product design by offering full immersion, 3D virtual reality to visualize and prototype ideas. The global Metaverse market size was estimated at USD 105.40 billion in 2024 and is projected to reach USD 936.57 billion by 2030, growing at a CAGR of 46.4 percent from 2025 to 2030. This new form of interactive space allows designers and engineers to see, touch and manipulate a product idea in real-time without the constraints of traditional CAD tools or the expense of physical prototyping. Rather than traditional forms of prototyping, the Metaverse offers full-scale digital prototyping, enabling better spatial awareness, to better factor in materiality costs and user experience right from the start. Stakeholders can enter a virtual room, interact with the model, and make collaborative decisions.

This technology enables quicker iteration, cross-functional collaboration, and easier collaboration with remote teams. Designers can present their ideas to clients or executives in an intuitive and engaging, allowing non-technical teams to visualize the product vision. It minimizes miscommunication between departments because everyone is working off the same model that evolves interactively.

For instance, Hyundai created a Metaverse showroom to let users “experience” cars virtually, influencing design choices based on real user interaction. These examples highlight how immersive virtual environments are not just about visualization—they are powerful tools for collaboration, feedback, and smarter product development.

Thomas Schemera Global CMO, Executive Vice president and Head of the Customer Experience Division at Hyundai Motor said, "To build innovative relationships with young people, we will strengthen our virtual customer experience content for familiarizing them with Hyundai Motor’s new vehicles and future mobility solutions on Hyundai Mobility Adventure, one of our next-generation CX platforms. We plan to continue to use the metaverse platform for communication of Hyundai Motor’s new vehicles and future mobility solutions, so please keep an eye on our upcoming content."

Advancing Product Innovation through Digital Twin Technology

Digital twins are transforming the way businesses monitor, analyze, and improve products during their lifespan. The global digital twin market Size is expected to reach USD 110.1 billion by 2028 from USD 10.1 Billion in 2023, growing at a CAGR of 61.3 percent during the forecast period from 2023 and 2028. Digital twins are virtual representations of physical objects, systems, or processes and are updated in real-time by sensors and devices. Using digital twins, designers and engineers can conceive authentic real world experiences, monitor performance, predict failures and augment performance long after its initial release.

Digital twins have powerful strands of real-time data leading to feedback loops allowing firms to work through "what-if" scenarios without affecting actual operations. Digital twins enable decision-making to take place at all levels of the product lifecycle. Digital twins allow for wide range of applications such as optimizing energy efficiency of machines, assessing maintenance requirements to reduce downtime and operational costs.

For instance, General Electric (GE) employs digital twins to monitor the real-time performance of its jet engines—tracking parameters such as temperature, vibration, and fuel consumption. This enables the company to predict component wear, support preventive maintenance planning, and optimize fuel efficiency.

Colin Parris, founder of GE's digital twin effort said, “A Digital twin, for me, is a living, learning representation of some form of asset or system. ‘Living' means there is a continual stream of data that allows the model to be aware of the environment. There's also feedback data: 'When I do an action, what's the result?'”

Siemens integrates digital twin technology across its factory operations through its MindSphere platform. By using partially replicable digital twins to simulate manufacturing lines before physical implementation, Siemens enhances productivity, improves quality, and reduces operational risks.

“Digital twins can keep on collecting data during a product’s operational lifetime,” says Dirk Hartmann, a leading expert on digital twins and simulations at Siemens Corporate Technology. “This can be information about physical stresses, components that have failed, or how an object—whether a milling machine, an aircraft, or a building—is used. Such information supports optimization during operations and also aids designers, architects, and engineers in preparing the next generation of a product.”

Blending Technologies for Smarter, Faster Innovation

The true innovation in product design comes when the Metaverse and digital twins are used together. The Metaverse allows for practices such as immersive ideation, collaborative real-time design, and visualization; digital twin provides data, accuracy, and real-world simulations. Together, they create a continual loop of intelligent design practice where ideas can be made, simulated, visualized, and validated, all from within the digital space.

This integration enables companies to design in the Metaverse and immediately validate those designs with performance simulations using digital twins. For instance, a designer explores how a product might feel, look, or function in a virtual digital space, while an engineer is evaluating mechanical stress, energy consumption, or durability or other considerations, in a digital twin model. This minimize design errors, speed ups development cycle, and ensure that both functionality and usability are accounted in the final product.

BMW has also embraced this combination in its manufacturing processes. At their Regensburg plant, BMW created a digital twin of the production line and linked it to immersive virtual experiences. Engineers can “walk” throughout the factory in the Metaverse, test layout changes, and predict outcomes using the twin—all before impacting the real world.

Michele Melchiorre, senior VP for production system, technical planning, tool shop and plant construction at BMW Group, said that before adopting digital twins and metaverse technologies, production systems in factories weren’t connected—3D models of buildings, layouts and products were separate. “With a virtual factory and the metaverse and digital twins, we bring all these things together, and we can use them together at any location where the people are.”

Likewise, Dassault Systèmes provides the 3DEXPERIENCE platform, which combines immersive collaboration with twin-enabled simulations to enable cross-discipline teams to collaborate on the co-design, prototype, test, and evaluate a product from inception to completion. This combination is leads to intelligent and efficient product innovation.

“Industry evolutions in the context of the Generative Economy are compelling automotive companies to make transformative decisions that will propel the vehicle experience to new heights,” said Pascal Daloz, CEO, Dassault Systèmes. “After four decades of partnership rooted in innovation and trust, we’re now embarking on the next chapter with Volkswagen Group with the 3DEXPERIENCE platform at its core. Our AI-powered virtual twins and the strength and resilience of the cloud will unify Volkswagen Group’s hardware and software innovation and unleash the knowledge and know-how to accelerate its software-driven transformation.”

Conclusion

As companies seek to innovate more quickly and more intelligently, the embrace of the Metaverse and digital twins is changing the future of product design. These technologies elevate creativity and collaboration while offering accuracy and data-driven understanding of every development stage.

“When combined with analytics, the concept of the digital twin delivers insights that can unlock hidden value,” says Rohit Gupta, vice president of products and resources for Cognizant. “It can provide engineers with information on potential operational failures of IoT-connected products, for instance, and thus help prevent unplanned downtime and improve product performance. The digital twin concept can also help solve challenges across the product value chain, such as lack of coordination and visibility of supply chain processes, limited cross-functional collaboration, and an inability to make data-driven decisions.”

Immersive visualization and real-time simulation allow companies to minimize costs, shorten timelines, and create better, user-centered products. From concept to launch, the digital ecosystem allows teams to make better decisions, faster. As the tools become increasingly embedded in the evaluation and design process, they will become essential frameworks of design innovation for all industries globally.

.jpg)